HERRA

Since our inception on November 11, 2004, Delco Switch Gears Pvt. Ltd. (DSPL) has been at the forefront of Power Electronics, Industrial Control and Automation, and their related fields. We have been actively involved in all phases of design and development, manufacturing, and application, earning widespread recognition and trust among our valued customers, including the esteemed Indian Railways.

DELCO is committed to a total quality management system, which is reflected not only by the ISO 9001:2015 certification, but also by the excellence of product range and most preferred supplier status.

At Delco, we are backed by a team of highly skilled professionals who always crave for enhanced quality, improved products and complete customer satisfaction. Owing to their reliability and unmatched performance, our products are popular not only in the Indian Railways but also amongst numerous Global Railways.

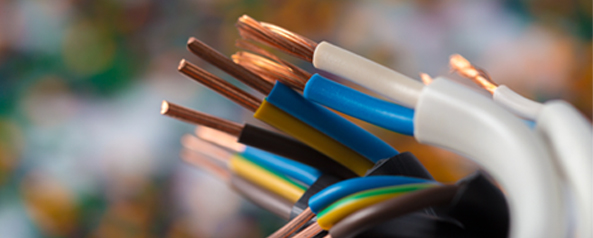

PTFE Wire & Cables

PTFE stands for Poly Tetra Fluoro Ethylene, which is a polymer insulation material made out of fluorocarbon. The ptfe wires covered with fluorinated polymer, provide excellent resistance to flame and are used in case of very thin dimensions. The non-conductive properties and high melting point of ptfe coated wires, make them a popular choice for electrical wiring and insulation for a variety of industries.

The PTFE Insulated Wire has the ability to providing a wiring system to exist in even extreme and demanding environments. So, instead of using traditional cables, you can think about using a PTFE wire for your applications and experience the benefits that come along with it.

You can subject a PTFE teflon coated wire to high resistance. Therefore, the temperature can create the least impact on the cable. PTFE High Temperature Stranded Wire has outstanding mechanical, thermal & electrical properties which makes it most suitable even at temperature ranging as high as 260°C and as low as minus 65°C

What makes PTFE wire different from other electric wires?

- The standard wires are made out of thermoplastic materials. However, PTFE wire is made with thermoset materials.

- PTFE High Temperature Stranded Wire can transfer current more effectively when compared to an ordinary wire.

- The dielectric constant associated with a PTFE insulated wire is much low and you can receive a higher level of electric permeability.

- The PTFE coated wire would not even flow above its melting point, which showcase its thermal stability.

- PTFE teflon wire offers excellent insulating performance, which can help you get the maximum out of a PTFE wire and continue to transfer current.

Technical Benefits of PTFE Wires & Cable

PTFE Cables Have Outstanding Mechanical & Electrical Properties. These Are Heat Resistant. Its Properties Qualify Them For An Ever-Widening Range Of Wiring A Applications, They Are Used In Many Situations, Where Temperature Is Between -65°C And +250°C. In most adverse uses, Where Chemical Fumes and Liquids would Render all other cables useless, PTFE Is the most well-known and durable Polymer and has been used in the cable industry for many years, It’s Outstanding Dielectric Properties, Even At Elevated Temperatures, Make It Most Suitable For Insulation Of Cables.

Segments of PTFE Wire & Cables

| PTFE Wire | PTFE Flexible Wire | PTFE CO-Axial Cables |

| PTFE Cables | PTFE Multipair Cables | PTFE Thermocouple Cables |

| PTFE Hook UP Wires | PTFE High Temperature Wires | PTFE Insulated Cables |

| PTFE Multi Core Cables | PTFE Hight Temperature Cables | PTFE Battery Wires |

| PTFE Brading Cables | PTFE Ignition Wires | PTFE High Voltage Cables |

| PTFE Sleeves | PTFE Tapes | |

| Any other customized customer requirement is also available | ||

Conductors Specification for PTFE Wires & Cables

| ABC | Annealed Bare Copper |

| NPC | Nickle Plated Copper |

| SPC | Silver Plated Copper |

| Any other customized customer requirement. | |

Colours Specification for PTFE Products

| RED | Black | White |

| Green | Orange | Yellow |

| Blue | Pink | Voilet |

| All Solid Colours | ||

| Any Bi Colour in Solid | ||

| Any other customer requirement is also available | ||

PTFE WIRES

Technical Specification

Brief Details Of Some Of Wires Are Provided Here Under. Never The Less The Company Offers Complete Range Of Products.

|

No. |

Size In AWG |

No. Of Strands/Dia Of Each Strand (MM) |

Parameters Of Conductor (Nominal) (As per JSS 51034) |

Nominal Dia Of Insulated Wire In AC/V |

|||||

|---|---|---|---|---|---|---|---|---|---|

| Dia. (MM) | Cross Section (sq. MM) | Resistance Ohm/km at 20° C | Elongation (Min) | ET(250) | E(600) | EE(1000) | |||

| 01 | 32/7/40 | 7/0.08 | 0.24 | 0.0340 | 570.9 | 5.5 | 0.56 | 0.74 | 1.00 |

| 02 | 30/1 | 1/0.25 | 0.25 | 0.0507 | 356.4 | 9.0 | 0.56 | 0.75 | 1.00 |

| 03 | 30/7/38 | 7/0.1 | 0.30 | 0.0568 | 332.3 | 5.5 | 0.61 | 0.81 | 1.07 |

| 04 | 28/1 | 1/0.32 | 0.32 | 0.0806 | 224.4 | 9.0 | 0.63 | 0.84 | 1.09 |

| 06 | 28/7/36 | 7/0.13 | 0.38 | 0.0887 | 210.5 | 5.5 | 0.69 | 0.89 | 1.14 |

| 07 | 26/1 | 1/0.4 | 0.40 | 0.1282 | 140.9 | 9.0 | 0.71 | 0.90 | 1.15 |

| 08 | 26/19/38 | 19/0.1 | 0.50 | 0.1540 | 126.7 | 5.5 | 0.79 | 0.99 | 1.24 |

| 09 | 24/1 | 1/0.5 | 0.50 | 0.2047 | 88.4 | 15.5 | 0.81 | 1.00 | 1.25 |

| 10 | 24/7/32 | 7/0.2 | 0.60 | 0.2270 | 83.2 | 9.0 | 0.91 | 1.12 | 1.37 |

| 11 | 24/19/36 | 19/0.13 | 0.63 | 0.2407 | 82.2 | 9.0 | 0.91 | 1.12 | 1.37 |

| 12 | 22/1 | 1/0.65 | 0.65 | 0.3243 | 56.1 | 20.0 | 0.95 | 1.15 | 1.40 |

| 13 | 22/7/30 | 7/0.25 | 0.75 | 0.3547 | 52.5 | 13.5 | 1.07 | 1.27 | 1.52 |

| 14 | 22/19/34 | 19/0.16 | 0.80 | 0.3820 | 49.8 | 9.0 | 1.07 | 1.27 | 1.52 |

| 15 | 20/1 | 1/0.8 | 0.80 | 0.5168 | 34.7 | 20.0 | 1.10 | 1.30 | 1.53 |

| 16 | 20/7/28 | 7/0.32 | 0.97 | 0.5630 | 33.0 | 13.5 | 1.27 | 1.47 | 1.73 |

| 17 | 20/19/32 | 19/0.2 | 1.00 | 0.6162 | 30.3 | 9.0 | 1.27 | 1.47 | 1.73 |

| 18 | 18/7/26 | 7/0.4 | 1.20 | 0.8969 | 20.7 | 13.5 | - | 1.75 | 2.00 |

| 19 | 18/19/30 | 19/0.25 | 1.25 | 0.9627 | 19.1 | 13.5 | - | 1.75 | 2.00 |

| 20 | 16/19/29 | 19/0.29 | 1.45 | 1.2293 | 14.9 | 13.5 | - | 2.03 | 2.25 |

| 21 | 16/37/32 | 37/0.2 | 1.40 | 1.200 | 15.0 | 13.5 | - | 2.00 | 2.20 |

| 22 | 15/19/28 | 19/0.32 | 1.60 | 1.5272 | 12.5 | 13.5 | - | 2.15 | 2.40 |

| 23 | 14/19/27 | 19/0.36 | 1.83 | 1.9412 | 9.5 | 13.5 | - | 2.42 | 2.69 |

| 24 | 14/37/30 | 37/0.25 | 1.75 | 1.8886 | 10.0 | 13.5 | - | 2.35 | 2.60 |

| 25 | 13/19/26 | 19/0.4 | 2.00 | 2.3864 | 7.8 | 13.5 | - | 2.60 | 2.85 |

| 26 | 12/19/25 | 19/0.45 | 2.25 | 3.0848 | 6.0 | 13.5 | - | 2.90 | 3.17 |

| 27 | 12/37/28 | 37/0.32 | 2.24 | 2.9742 | 6.5 | 13.5 | - | 2.85 | 3.12 |

| 28 | 11/19/24 | 19/0.5 | 2.50 | 3.7287 | 5.0 | 13.5 | - | 3.15 | 3.40 |

| 29 | 10/19/22 | 19/0.65 | 3.20 | 6.3015 | 3.0 | - | - | 3.80 | 4.10 |

| 30 | 10/37/26 | 37/0.4 | 2.82 | 4.7397 | 3.9 | 13.5 | - | 3.40 | 3.68 |

| 31 | 8/133/29 | 133/0.29 | 4.29 | 8.6054 | 2.2 | 13.5 | - | 0 | 5.31 |

| 32 | 6/133/27 | 133/0.36 | 5.41 | 13.5889 | 1.4 | 13.5 | - | 0 | 6.68 |

Apart from the above size and voltage customized size wire with customized voltage is available against special orders.

PTFE Cable

PTFE Cables are the most durable and tough quality cables as these are insulated with Polytetrafluoroethylene which is a synthetic fluoropolymer of tetrafluoroethylene, a kind of polymer plastic. You will be impressed with the excellent mechanical composition that a PTFE insulated cable can offer. Due to the perfect mechanical composition, you may use ptfe coaxial cable for numerous applications that you have to deal with in day-to-day life.

PTFE teflon is very flexible but very tough and durable material due to tetrafluoro polymer inside which gives it a very strong and properties to sustain any kind of harsh conditions where the wires can get scratched, cut or burn.

Composites & laminates engineered for corrosive environment & severe temperature. Moisture is not good for electric wires at all, however, when you are using a PTFE cable, you can overcome that worry as well. That’s because the ptfe insulated cable is boasting zero moisture at all times.

PTFE Hook-Up Wire

The Hook up wire is a type of copper wire with a single, ptfe insulated conductor, that is either solid or multiple thinner strands bundled to equal a thicker gauge. PTFE Hook up wire is small-to-medium gauge, solid or stranded, teflon insulated wire, used for making internal connections inside electrical or electronic devices. Teflon insulated hookup wire is often tin-plated to improve solderability.

PTFE Hook Up Wire is the best quality of raw material in a perfect ratio is used to manufacture our offered wires and cables. These ptfe hookup wires are precisely tested for tested conductivity, tensile strength by our dexterous professional which

helped us to come up with such distinct range. Teflon insulated hookup wire and cables are available in full range of sizes and shapes at industry-leading prices

The Hook up wire - Key Applications

The high temperature hook up wire is a single insulated conductor that is used for low current, low voltage (usually under 1000 volts) applications within enclosed electronic equipment. It can operate under extreme temperature that may range from -40 deg. C to 105 deg. Celsius. The high temperature hook up wire comes with color coded PTFE insulation and is corrosion proof.

- Hook up wire, is also known as a lead wire, is a single core teflon insulated hookup wire used in the internal wiring of electronic and electrical equipment.

- Specific applications include motors, transformers, switchboard, panels, rectifier and electronic circuits.

- Teflon Hook up Wire is frequently used in control panels, automotive, meters, ovens, internal wiring of computers, electronic equipment, business machines, and appliances.

- Our Hook up wire is most often used within enclosed electronic equipment, and certain types may even be used in challenging military applications.

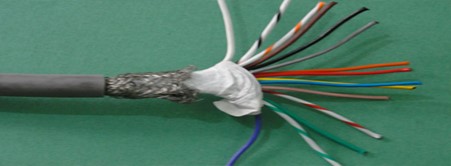

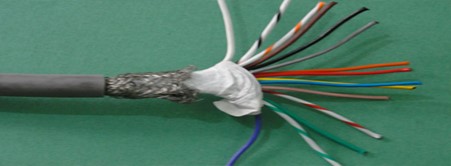

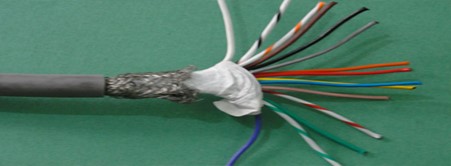

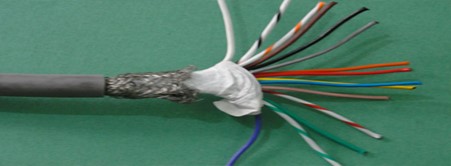

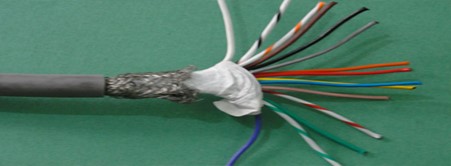

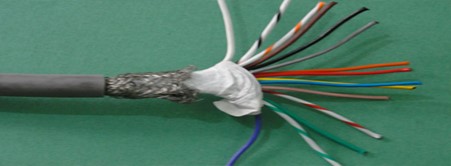

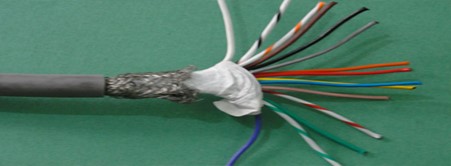

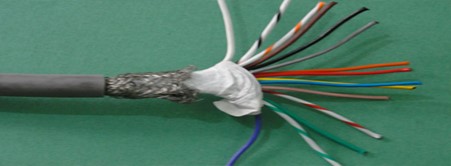

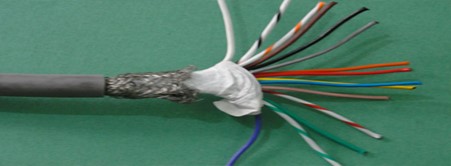

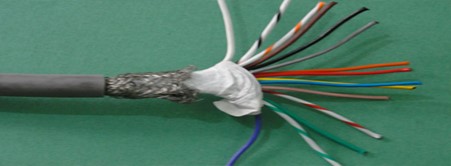

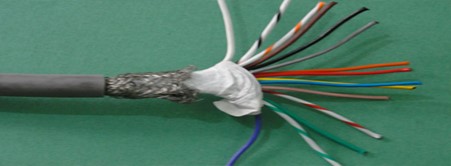

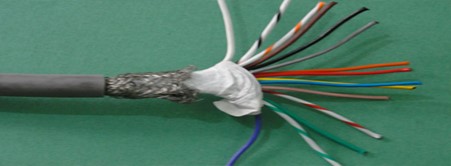

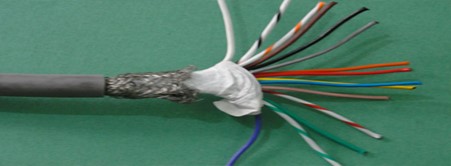

PTFE Multicore Cables

A PTFE insulated multicore cable is a type of electrical cable that combines multiple signals or power feeds into a single jacketed cable. This jacket adds significant mechanical protection, making the flexible multicore cable much more rugged. A multi core wire cable has an outer sheath which surrounds all of the inner conductors.

multi core wire is extremely versatile and are used for all kind of applications, especially those which would otherwise call for a high volume of cables.

Industrial Applications of Multicore Cable

The flexible multicore cable is often used to simplify the physical setup of a system and provide a neater connection between two pieces of equipment.

Resistance to fire, chemicals, acids, sunlight, moisture and corona. A multi core wire cable can be used for analog and digital signals as well as power distribution. Multicore cables are also used extensively in entertainment, with concert venues and theatres often utilising cables combining power, data and AV to avoid a tangled mass of cables running across the stage!

Flexible multicore cables are often joined with power cables for CCTV use, meaning that only one cable has to be run to provide a both video and power connections.

Space-saving :

A multicore cable takes almost 40% less space than cables with similar functions. By combining multiple conductors with different functionalities in one cable, we end up saving space. PTFE Multicore coaxial cables are often used in electronic equipment and for applications where space is limited, such as aircraft and medical equipment.

PTFE Flexible Wires

Flexible wires are electrical cables specially designed to deal with the tight bending and physical stress related to moving applications, like inside cable carriers. For large ampacity, diesel locomotive wire, known as flexible PTFE, is the most flexible of all cables. They consist of hundreds of very small strands in flexible cable 3 core are made for use in confined spaces.

The use of 2 core flexible wire conduits of this type can simplify the changing, replacement, and upgrading of particular sections of a system. Even in industrial applications when a component part of a machine is to have different locations of operation essentially the particular component is to be always connected to the 4 core flexible cable power source for the part to function and perform.

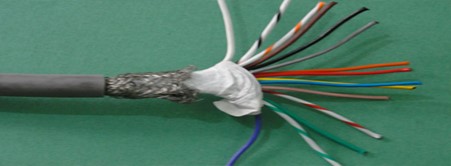

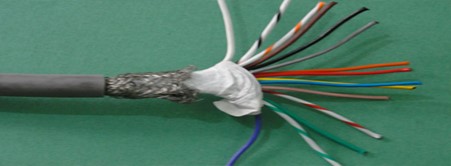

PTFE Multipair Cables

PTFE Multipair cables basically the PTFE multipair cables are multiple paired cables in one single cable many PTFE cables form a pair and these pair of multiple cables form a single cable called PTFE Multipair cables.

PTFE Multipair Cables types of cables have very high flexible life and these wires can easily sustain extreme temperatures and chemical environments as few industries demands very high reliability of wires in extreme temperature and chemical environments specially in chemical plants these wires need to perform with their electrical properties in all these kinds of tough environment maintaining.

Reliability of PTFE Multipair Cables also keeping in mind the various industry standards and various industries interface and their needs due to which these wires need to survive well.

Multi pair cables are widely used in telecom industry, electronics and networking industry. It has been seen that in networking industry data load is very high due to which it requires PTFE Multipair cables with very high reliability and SSI Cables and wires manufactures best quality of PTFE wires and cables.

PTFE High Temperature Wires & Cables.

high temperature PTFE wires these wires can resists high temperature ranging from 250 degree centigrade to 260 degree centigrade at such a high temperature these wires are stable and working fine this happens due to these wires inertness as this prevents these wires to form cross linking high and harder thermo set which in turn will minimizes the flammability.

PTFE High Temperature Wire allows these wires PTFE high temperature wires to act as a excellent insulation for thermal or electrical and thermal insulation and another quality is that these PTFE wires will not get affected at low temperatures also at low temperatures these wires will maintain a very good flexibility strength without compromising any of its wire functions as

PTFE has a very strong molecular structure with repeated atoms of carbon with fluorine atoms due to this basically these wires is not wetted with water as both carbon and fluorine atoms minerals are dissolved to sulfuric acid which results in creation of hydrofluoric acid as a result this acid is formed to develop tetra flouro ethylene resins and these are very desirable properties of PTFE. Due to this property SSI manufactured PTFE wires do not get easily wetted into water as fluorine molecule is highly electronegative.

PTFE Coaxial Cables

Coaxial cable is a type of PTFE cable specially built with a copper shield and other metal components engineered to block signal interference. The woven copper shield between the dielectric insulator and outer jacket creates an electromagnetic shield to block interference. Notably, the braids of this shield in coaxial cables are peeled back during connector crimping which reduces undesirable effects like passive intermodulation and potential ground loops.

A coaxial wire is just what the name implies - it is a two-conductor cable in which both conductors share the same physical axis. Many use of coaxial cable can be placed in a single outer sheathing and, with repeaters, can carry information for a great distance. Teflon Coax can be a much more efficient means of getting RF cabling power from one place to another with minimum loss.

RG-188A/U is a Teflon cable with insulation that allows flexible shields for the centre conductor. This is the Best coaxial cable, silver plated copper covered steel as inner conductor, PTFE dielectric, Silver Plated copper as braid wire, and PTFE as jacket.

RG188 coaxial cables are used in wireless communication, broadcast and military equipment’s for transmission of radio frequency signals.

RG188 coax having a centre conductor and shield around this centre

conductor is often needed for coaxial cable in networking when it is needed to keep external signals out of the cable. Other specifications that may be included are shield coverage (coaxial cable in computer network), the specifics of the cable construction.

PTFE Thermocouple Cables

The thermocouple cable consist of two wire legs made from dissimilar metals which are fixed together at one end, creating a junction. If the two junctions are held at different temperatures, an electrical potential is produced. When this junction experiences a change in temperature, a voltage is created, this voltage can then be measured and referenced back to the thermocouple wire temperature.

PTFE Thermocouple cables are used for sensing temperatures ranging from low temperature of - 65 degree centigrade to high temperature of 200 degree centigrade. A thermocouple is an electrical circuit with two dissimilar metal wires using copper conductors plated with silver and using a nickel plate copper conductor.

The thermocouple wire types are varies from the two

K type thermocouple wire

Nickel-Chromium or Nickel-Aluminium: Most common is the couple called “K”, made with on one side a Nickel/Chromium alloy, called Chromel, and the other side a Nickel/Aluminium alloy, called Alumel. The K type thermocouple wire has a positive leg of Chromel (90% nickel, 10% chromium) and a negative leg of Alumel (95% nickel, 2% aluminum, 2% manganese and 1% silicon). K type thermocouple wire is a common type of thermocouple can be found anywhere, due to be resistant to radiation is used in nuclears plants, its grade wire is -270 to 1260 celcius, the extension grade wire is 0 to 200 celcius.

Type J Thermocouple wire

Iron–constantan: They have a sensitivity of 55 μV/°C and are the preferred type for general purpose measurements in the temperature range of −40 °C to +750 °C, where the typical measurement inaccuracy is ±0.75%. Type J Thermocouple wire performance is little affected by either oxidizing or reducing atmospheres.

A thermocouple generates voltage when two dissimilar metals have a measuring junction and a reference junction The thermocouple cable connecting the measuring and reference junctions must be made of the same metals used to avoid errors caused by introducing additional thermocouples. A thermocouple wire is a sensor used to measure temperature in a number of processes.

There are three major thermocouple cable uses for this phenomena

Temperature sensing

If first junction is held at a reference temperature, a voltage is produced in compensating cables as a result of the temperature difference between the second junction. The proportionality between the temperature and voltage depend on the material used. A commonly used material pair is k type thermocouple wire.

Power production

With the same setup as above, and several or more thermocouple wire types of series can produce power. The Voyager spacecraft use such an arrangement of compensating cables with a Plutonium ring providing heat source. It provides the power for the spacecraft instrumentation and communications radio.

Cooling/heating

The same principal can be used in reverse, to provide heating or cooling between two points of thermocouple cable when an electrical current is supplied. The compensation is required because for every wire connection in the thermocouple circuit, typically the compensating cable shows an error voltage, or current, is introduced. This error requires correction.

PTFE Insulated R.T.D. Cable

PTFE Insulated wires are highly heat resistant wires, not only heat resistant but they also have good durability and longer life as these wires cannot be cut very easily and these wire do not even melt easily as a result it gives a longer life to the wires.

PTFE Insulated RTD Cable is basically temperature sensor wires.

These wires are used to measure the temperature using a very simple principle which is, metal will change its resistance when there will be a change in the temperature and for the application of PTFE Insulated RTD Cable electrical charge is released and transmitted from a metal piece which we called Resistance Temperature Detector (RTD) sensor or we can say resistor which is located in a near distance.

RTD Cables are used in laboratory to get accurate and genuine measurements for various kinds of temperature range. SSI has all kinds of RTD cable.

PTFE Battery Wires

A Battery wire needs good insulation with flexibility. In cold weather, all other types of inverter battery wire connection become very stiff and difficult to work with due to the already limited flexibility. Therefore, our connecting Battery Cables are made of PTFE insulated wires and these battery wires are wrapped in a thick band of flexible and heat resistant Teflon coating material.

The inverter battery cable is offered in sizes ranging from 6 AWG to 4 AWG. Connecting battery cables is the best option when simple connection and protection is needed. This is to provide strong insulation to battery wire, produces direct current of more than 12 volts.

These inverter battery connection need insulated durable PTFE wires because inverter battery wire connection store more energy to provide a longer life. Due to which batteries become essential product as connecting battery cables have chemical energy which converts into electrical energy to fulfill the needs of direct current.

EV Charging Cable with Teflon Coating

In order to protect the EV cables from outside sources and to give the EV charger cable a longer life, PTFE is a polymer stand with good qualities. It has various fluorocarbons due to which our EV charging cable has very good performance. An inverter battery connection is available in standard battery circuit cable red and black.

An ordinary battery wires are limited to applications or projects that need no more than 60 volts of power. Therefore, teflon coated EV charging cable is the ideal solution for situations in which a simple connection between a battery and a starter is needed.

PTFE Braiding Cables

Braiding cable is a type of shielding that consists of fine metallic strands, tightly woven together into a meshed tube-like formation. Braided copper wire is usually used around a center conductor with insulation between to shield the center conductor from outside electrical interference.

Braided teflon wire is easier to insulate and also is less subject to breakage from movement. At high frequencies a conductor carries most current in the outer area of its cross section. PTFE high temperature stranded wire increases this area for a given wire size and improves conductivity at increasing AC frequencies. Solid braided ptfe wire is easier and cheaper to make and is used where a more rigid connection is required.

Braided wire Electrical Properties

Braided wire offers a shielding to the signal from external interference and still remains flexible. The same goes for ptfe high temperature stranded wire, its major use is allowing flexibility for use in elevators and any other use that requires movement of the wire itself.

Braiding cable along with stranded wire is used where movement of the wire will regularly happen with usage. The strands can flex without becoming work hardened and brittle, causing it to break. Braided ptfe wire is capable of being bent many times before breaking and is used in areas where constant movement is expected, for example the earth lead on car battery wire.

PTFE Ignition Wires

An ignition cable is any wire carrying high voltage to the spark plug wire. It transmits electrical power to the spark plug cable for a specific time and duration to ignite the fuel in the engine’s combustion chamber. Spark plug wires transfer the spark from the distributor or ignition cable to the plugs. The subsequent spark ignites the air-fuel mixture in the combustion chamber of your engine.

The ignition cable carries the electric current from the alternator to the next point of usage. Here the electronic device used the current to fire the spark plug cable which in turn burn the fuel which enters the combustion chamber. It can be either the plug wire between the coil and the distributor or between distributor and spark wire.

On newer computer run cars, each spark plug cable has its own spark coil as an integral part of its plug wire, fired by the computer, so a single coil and distributor are no longer used. This spark wire terminal controls the car's ignition switch wiring and other electrical features. On older cars they would run from the ignition wire to the distributor, then from the distributor to the individual spark plug wire.

PTFE High Voltage Cables

A high voltage cable (HV Cable) is a type of Teflon coating used for electric power transmission at extra high voltage cable. They are considered to be fully insulated ptfe wire which means they have a full rated system which will consist of insulation, semi-con layers, and a metallic shield. The high voltage power cables have distribution wires and can go as high tension cable as 750,000 volts.

Using high voltage power cables is very imperative, it is recommended that the person should undergo a strong research and evaluate each and every parameter. So that any type of hazardous situation can be avoided or accordingly safety plans can be formulated.

PTFE Insulated Sleeves

We offer widely appreciated PTFE Insulated Sleeves at industry leading prices. Our insulated sleeves are strong and suitable for underground and open air connections as well. They are resistant to fire, chemicals, sunlight and moisture. These sleeves are made available in different colors and customized dimensions. We assure safe and timely delivery of Teflon insulated sleeves.

PTFE Insulated Sleeves

Poly Tetra Fluoro Ethylene (PTFE) is a synthetic polymer with excellent dielectric insulation properties. We offer premium quality PTFE Sleeves at industry leading prices. It is highly resistant to fire, chemicals, acids, sunlight and moisture. In its manufacture we use best quality raw materials while the colors and dimensions are defined by our clients. Our product is durable and applicable in corrosive fluid pipelines, insulation sheathing and coated shafts.

Specifications:

- Inner Bore Size : 0.5 mm to 40 mm

- Wall Thickness : 0.25, 0.30, 0.40 & 0.80 mm

- Break Down Voltage : Upto 17 KV

- Temperature Range : - 65°C to + 200°C

- Standards Applicable : JSS 54802 / MIL - 122129 C

|

No. |

Bore |

Wall Thickness |

Break Down Voltage |

||

|---|---|---|---|---|---|

|

|

Nominal (mm) |

Tolerance +(mm) |

Nominal (mm) |

Tolerance +(mm) |

AC (K. Voltage) |

| 01 | 0.50 | 0.10 | 0.25 | 0.005 | 11.5 |

| 02 | 0.75 | 0.10 | 0.25 | 0.005 | 11.5 |

| 03 | 1.00 | 0.10 | 0.30 | 0.005 | 14.6 |

| 04 | 1.50 | 0.15 | 0.40 | 0.008 | 16.3 |

| 06 | 2.00 | 0.15 | 0.40 | 0.008 | 16.3 |

| 07 | 2.50 | 0.15 | 0.40 | 0.008 | 16.3 |

| 08 | 3.00 | 0.15 | 0.40 | 0.008 | 16.3 |

| 09 | 3.50 | 0.2 | 0.5 | 0.1 | 17.0 |

| 10 | 4.0 | 0.2 | 0.5 | 0.1 | 17.0 |

| 11 | 5.0 | 0.2 | 0.5 | 0.1 | 17.0 |

| 12 | 6.0 | 0.2 | 0.5 | 0.1 | 17.0 |

| 13 | 7.0 | 0.2 | 0.5 | 0.1 | 17.0 |

| 14 | 8.0 | 0.2 | 0.5 | 0.1 | 17.0 |

| 15 | 9.0 | 0.2 | 0.5 | 0.1 | 17.0 |

| 16 | 10.0 | 0.2 | 0.5 | 0.1 | 17.0 |

| 17 | 12.0 | 0.2 | 0.5 | 0.1 | 17.0 |

Cured PTFE Tapes / Sheets

Our organization is the manufacturer & exporter of Cured PTFE Tapes / Sheets. We produce these products using high grade of raw material.

Cured PTFE Tapes / Sheets

We offer an unusual, reliable non-sticking cured PTFE Tape which is useful at high temperature slot-liner (up to 300°C). The tape offers the best possible overall electrical characteristics with complete freedom for ageing. The range of thickness is from 0.075 mm to 0.4 mm. In comparison to the unsintered PTFE Tape (which is best available sealant threaded joints & fittings), it is about 5 to 10 times stronger mechanically. Its density is about 2.1 compared to

|

Features |

Specifications |

|---|---|

| Repositionable without residue | Density : 0.15 -2.0 g /cm3 |

| Conforms nicely , non -stick | Width : 2-100 mm |

| Heat, moisture and chemical resistant | Length :5-50 mm |

| Easy Release | Thickness: 0.075-2.0 mm |

| Low Friction | Material : PTFE |

| Anti-static |

Specification followed

|

Sr. No. |

Products |

Specification |

|---|---|---|

| 01 | PTFE insulated equipment wires Sizes AWG 06 to AWG 32 Voltage grade:250v, 600v, 1000v |

JSS 51034 (Equipment Foreign standard MIL-W-16878/NENA HP3) |

| 02 | Multi cores/pair Shielded / un shielded cables | JSS 51038 (Equipment Foreign standard MIL-DTL-27500H) |

| 03 | PTFE Electrical sleeving Bore: 0.50 mm to 25.00 mm | JSS 54802 (Equipment Foreign std MIL-I-22129) |